Cap Liner - China Manufacturers, Suppliers, Factory

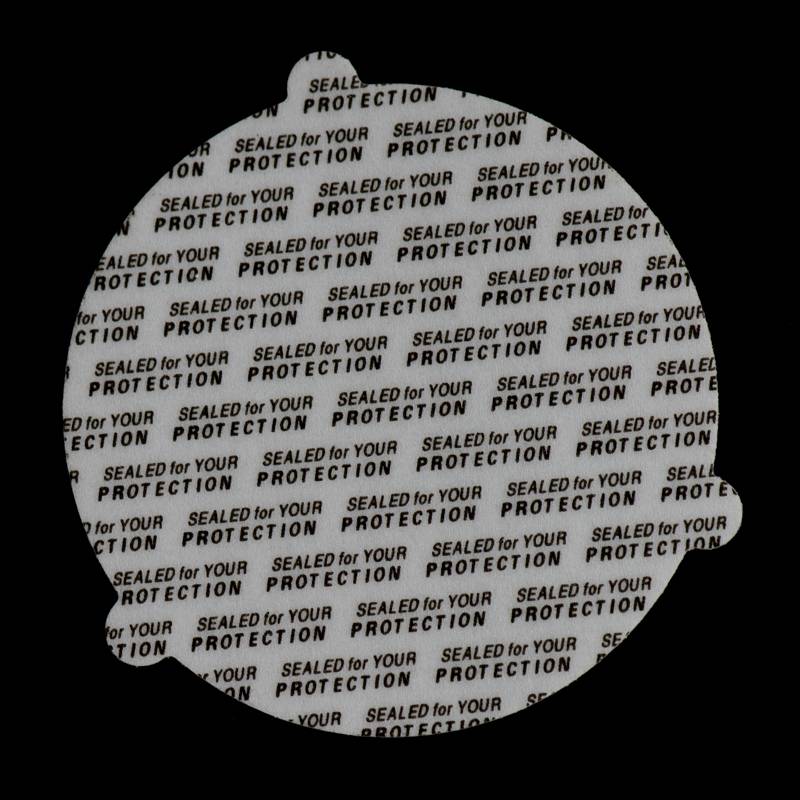

To continuously increase the administration process by virtue of the rule of "sincerely, good religion and excellent are the base of company development", we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for Cap Liner, Induction Aluminum Foil Seal, two Piece Aluminum Foil Seal, Induction Seal Liner For Glass Bottle,Glass Induction Seal. We sincerely hope to serve you and your business with a good start. If there is anything we can do for You, we shall be more than pleased to do so. Welcome to our factory for visit. The product will supply to all over the world, such as Europe, America, Australia,Guatemala, Germany,Morocco, Naples.We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Related Products