Seal Induction Liner - Factory, Suppliers, Manufacturers from China

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Seal Induction Liner, Pp Bottle Induction Cap Seal Liners, Seal, Seal Foil Liner,Aluminum Foil Induction Liner. We are looking forward to receiving your enquiries soon. The product will supply to all over the world, such as Europe, America, Australia,Canberra, US,California, Jeddah.As operation principle is "be market-oriented , good faith as principle, win-win as objective", holding on "customer first, quality assurance, service first" as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

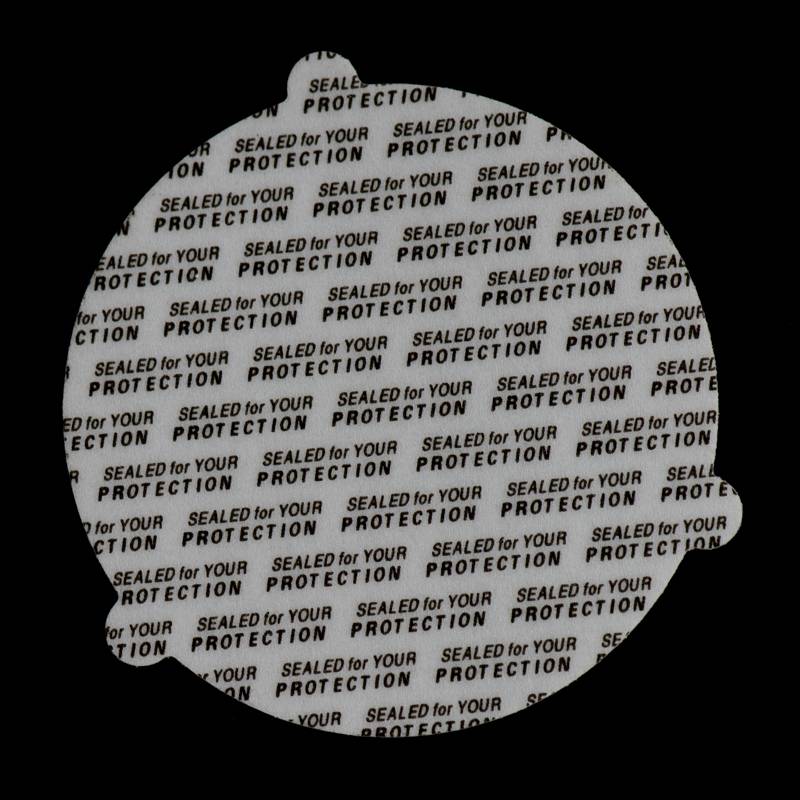

Related Products